Lean consulting Services

Empower Your Operations with Expert Consulting

Allied consulting services focus on providing tangible and measurable improvements to your warehousing and manufacturing operations.

Through a systematic and calculated approach, we help our clients to map their current state, envision their future state, and identify the projects needed to get there.

With a focus on standardization, lean improvements, and process verification, we provide turnkey, sustainable solutions for our clients.

Problems we see

Lean Logistics

Customized Approach

01.

Evaluation

Our consultants begin by conducting a comprehensive evaluation and analysis of your processes, from your supply chain and warehouse operations to your management, staff, and existing digital tools.

02.

planning

Using a lean-based approach, we identify areas for improvement then develop a plan to execute our recommendations.

03.

Execution

We provide a roadmap with processes for training, accountability, and measurement to ensure your team stays on track.

Our Results

Improvement Methods

Empowering Management

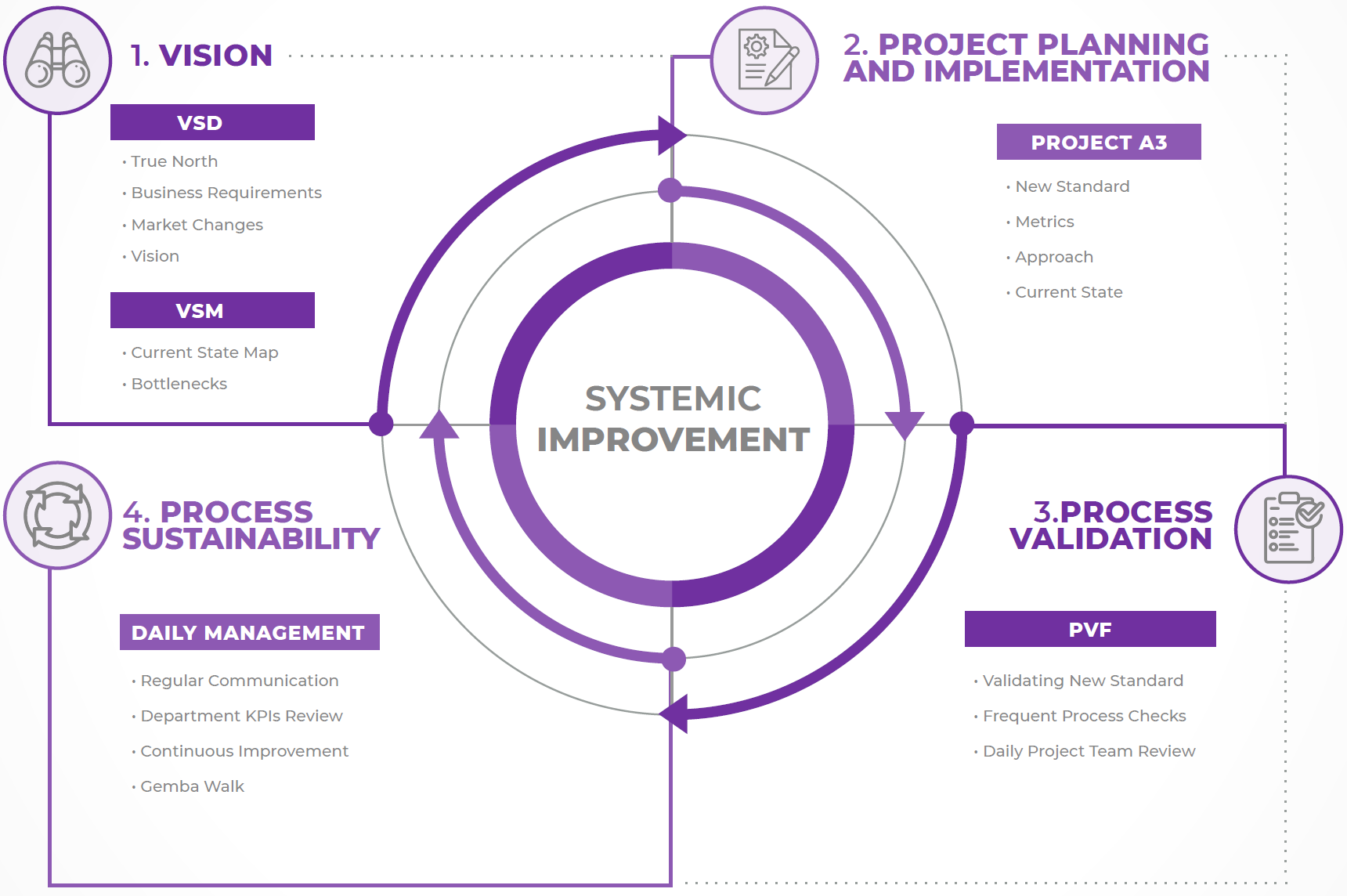

Our systemic approach to continuous improvement plays an integral role in the lean transformation of your operation. We work to empower management with the skills and tools they need to identify manpower strengths and resolve weaknesses affecting the overall culture and workflow structure.

1. Your Vision

Our process begins with a clear vision —your True North. This vision is rooted in a thorough understanding of business requirements, responsive to market changes, and dedicated to crafting a strategic path forward.

We delve into your Value Stream Mapping (VSM) to assess the current state of operations, pinpoint bottlenecks, and illuminate the path to your ideal future state.

2. Project planning and Implementation

Our project planning and implementation revolve around the PROJECT A3 framework. This disciplined method sets new standards, establishes key metrics, and outlines actionable approaches. We evaluate your operations as they are, setting the stage for impactful change.

3. Process Validation Form

At the core of our methodology is rigorous process validation. Our Process Validation Form (PVF) ensures that new standards are not only met but are consistently aligned with our high benchmarks. Through frequent process checks and daily project team reviews, we maintain a close eye on progress, guaranteeing that every step taken is a step toward improvement.

4. Project planning and Implementation

Sustainability is not an afterthought; it's woven into every layer of our process. Daily management practices, such as regular communication, departmental KPIs review, continuous improvement, and Gemba Walks, ensure that the improvements we implement endure. We don't just set the standard—we make it stick.

Let’s Work Together to Achieve Results

Schedule a Complimentary Consultation Today

Overcoming Challenges

Success Stories

Explore our case studies to experience the profound transformation our services have wrought upon industry leaders. These narratives vividly illustrate the potent force of change that has unlocked exponential revenue growth while simultaneously slashing costs.