The LiftLiner is a unique tugger train solution for internal logistics and an excellent choice for forklift-free environments.

With the LiftLiner you avoid the complexities of sequencing deliveries to the production line in advance. Loading of different sized carts from both sides without the need to modify the LiftLiner truly enables a streamlined logistics process. Its compact design ensure that you minimize the space needed for production logistics significantly.

The special tilting technology of our LiftLiner tugger train even makes the loading and unloading process highly operator friendly. It only takes 3 seconds to lift up to 1000kg and be ready to continue the route. Lean logistics has never been easier.

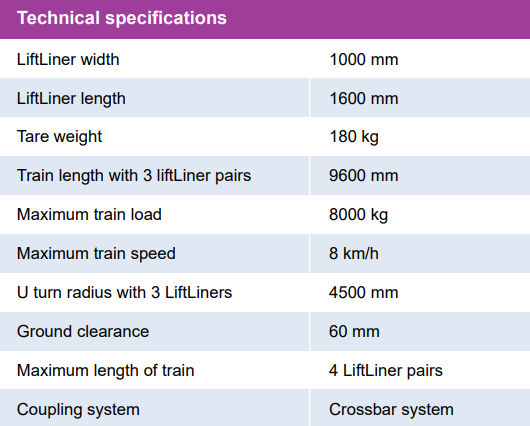

Technical Specifications

| LiftLiner width | 1000 mm |

| LiftLiner length | 1600 mm |

| Tare weight | 180 kg |

| Train length with 3 liftLiner pairs | 9600 mm |

| Maximum train load | 8000 kg |

| Maximum train speed with 3 or 4 LiftLiner pairs | 8 km/h |

| U turn radius with 3 LiftLiner pairs | 4500 mm |

| Ground clearance | 60 mm |

| Maximum length of train | 4 LiftLiner pairs |

| Coupling system | Crossbar system |

Key benefits

- Very compact and agile

- Enables a fork-lift free production environment

- Low total cost of ownership

- Loading/unloading from either side at point of delivery

- Fast and safe (un)loading

- No sequencing needed – allows a more flexible supply of the production line

- Very safe and ergonomic to use